Induction Heating Working Principle-Applications

Induction heating is a process that utilizes Faraday’s law of electromagnetic induction to generate heat. A magnetic field is created by bypassing an alternating current (AC) through a coil. This magnetic field then induces eddy currents within the conductive material, causing it to heat up.

Induction Heating Working Principle

Induction heating is a process wherein an alternating electric current generates heat in a conductive material. It relies on the principle of electromagnetic induction.

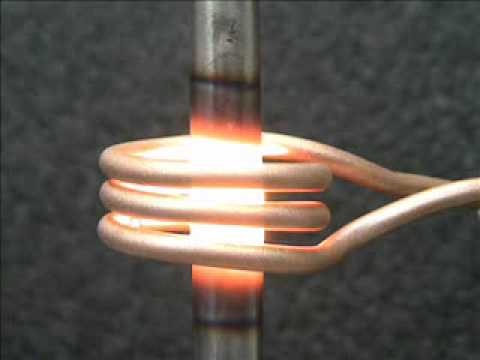

The process begins with an alternating current (AC) passing through a copper coil, known as the induction coil. This coil creates a magnetic field around it. When a conductive material is placed within this alternating magnetic field, eddy currents are induced within the material. These eddy currents generate heat due to the material’s resistance to the alternating current flow, resulting in rapid and efficient heating.

The frequency of the alternating current determines the depth of penetration and heating profile. Higher frequencies result in more localized heating, while lower frequencies offer deeper and more uniform heating.

Applications

- Metal Processing: Induction heating is commonly used for metal heat treatment processes such as hardening, annealing, tempering, and stress relieving. It allows for precise control of heating parameters and rapid heating, improving productivity and product quality.

- Forging and Shaping: It is used in forging processes to heat metals and alloys to their ideal temperature for shaping operations. It enables precise temperature control and reduces heating time, resulting in superior mechanical properties and enhanced production rates.

- Cooking and Food Processing: Induction cooktops utilize induction heating to heat the cookware directly instead of relying on traditional heating elements. This technology offers faster and more responsive heating, precise temperature control, and energy efficiency.

- Semiconductor Industry: It is employed in the manufacturing processes of semiconductors, including bonding, soldering, and annealing. It ensures precise and controlled heating, reducing thermal stress and enhancing product reliability.

Advantages

- Efficiency: It is highly efficient due to its direct transfer of energy to the material being heated. It eliminates the need for intermediate heat transfer media like air or water, ensuring minimal energy loss.

- Rapid Heating: It offers rapid heating speeds compared to conventional heating methods, reducing production cycle times and improving overall productivity.

- Process Control: The ability to precisely control heating parameters such as power, frequency, and time allows for efficient and consistent heat treatment. This results in improved product quality and reduced scrap rates.

- Safety: Induction heating eliminates open flames, reducing the risk of fire hazards. Additionally, the absence of heating elements minimizes the chances of accidental burns or contact injuries.