Single-phase salient pole synchronous motors are called reluctance motors. the stator of the reluctance motor has the main winding and the auxiliary winding the same as the single-phase induction motor.

The motor starts as an induction motor. It is pulled into synchronism with the ac supply by reluctance torque developed at salient iron poles which have a lower reluctance air gap.

Construction of Reluctance Motor

The reluctance motor consists of:

Stator

Stator has single-phase winding along with the auxiliary starting winding to produce a synchronous revolving magnetic field as single phase motor.

Rotor

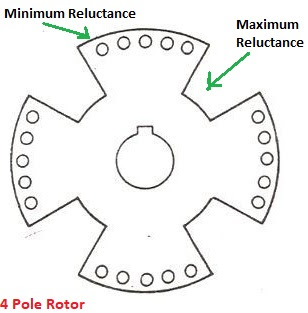

The rotor of the reluctance motor is squirrel cage type with some modification. reluctance motor rotors some teeth are removed at definite places such as to create the salient poles on the rotor.

The below diagram shows that 4-salient poles have been produced on the rotor.

The rotor bars are not removed even in the space from where teeth are removed. the two ends of the rings short circuit these bars same as the squirrel cage rotor.

Working Principle of Reluctance Motor

When the stator of the reluctance motor is connected to a single-phase supply. the rotating magnetic field is produced in the stator and starts as the induction motor initially.

When the motor reaches a speed up to 75% of synchronous speed, the centrifugal switch operates and disconnects the auxiliary winding and the motor continues to run as a single-phase induction motor with the main winding in operation.

When speed is close to synchronous speed a reluctance torque is produced due to the tendency of the rotor to along itself in the minimum reluctance position with respect to the rotating flux of the stator winding. the rotor pulled onto synchronism.

After attaining synchronism the induction torque disappears but the rotor keeps itself in synchronism due to synchronous reluctance torque.

The advantages of reluctance motors are simple construction, low cost, and easy maintenance.

Disadvantages of this motor are rotor is unexcited and saliency, power factor is low as compared to an induction motor of the same rating.

this motor can generate only 1/3 of power as compared to an induction motor of the same size with a cylindrical rotor.

Uses of motor: Despite its shortcomings motor is used in constant-speed applications

- in recording instruments

- regulators

- In recording instruments

- regulators

- Clocks

- Tele printers

- Gramophones

- Analog electric meters

- Electric vehicles

- Power tools like drill