4 Point Starter: Working Principle ,Construction and advantages

The armature will draw a very high current due to the small resistance of the armature winding to avoid this heavy starting current 4 Point starter is used. Here we are going to discuss the 4-point starter it’s working principle and construction

Mainly two types of starters are used

- 3 Point starter

- 4 point starter

Working Principle of 4 Point Starter

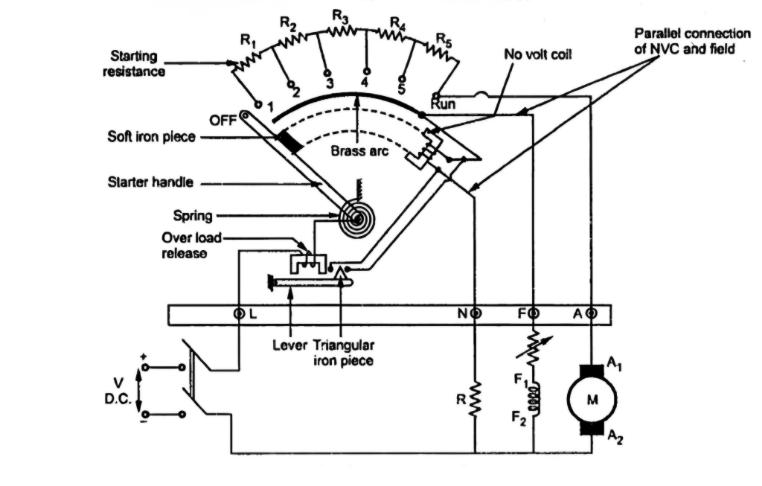

Four-point starter shown in the above diagram is connected to the DC supply and DC shunt motor.

Under the normal running conditions of the motor, the handle is in the RUN position, and the holding coil is in series with the starting resistors and additional resistance “R”.

4 Point starter insert starting resistors in series with the armature circuit.

- For starting the motor, the starter handle is moved to the first stud indicated with 1 and all resistors are connected in series with armature Winding.

- Since the current starts flowing through both field and armature winding the motor starts rotating.

- After reaching sufficient speed the Starter handle shifted to stud 2, Hence it cut down the resistance between stud 1 & stud 2.

- The movement of 4 point starter handle continued till the soft iron keeper touched the holding magnet.

- During the shifting of the handle from stud 1 to stud 6 the speed of the DC motor increases gradually.

- In the final position, the electromagnetic pull exerted by the holding coil will be greater than the force exerted by the spiral spring.

- In this view, the starter handle is held in the RUN position and the entire starting resistances are cut out. The holding coil HC is also called a NO-Volt release or low volt release.

4 Point Starter Construction

4 point starter has four terminals named L, N, F, and A.

Series resistors R1, R2, R3, R4, and R5 are connected in series with armature Winding as shown in the above wiring diagram.

- Positive of DC supply connected to terminal ‘L’ Line terminal

- Terminal ‘A’ Armature terminal Connected to the armature winding

- Terminal ‘F’ Field terminal Connected to the field winding

- And fourth terminal N Connected to the No Voltage Coil (NVC)

The main difference between the 3 point starter and the four-point starter is that the holding coil is removed from the shunt field circuit and connected across the line with series resistance “R”.

The function of resistance R is to prevent a short circuit of the main supply In case of overload release OR operated

Difference between 3 Point Starter and 4 Point Starter

The main difference between a 3 point starter and a 4 point starter is that the 4 point starter has a holding coil that is removed from the shunt field circuit and connected across the line with series resistance R.

This configuration helps prevent a short circuit of the main supply during overload release.

On the other hand, a 3 point starter does not have this additional resistance and the holding coil remains connected to the shunt field circuit.

This variation in the circuitry allows for different levels of control and protection in the operation of DC motors.

4 Point Starter advantages

The 4-point starter offers several advantages over other DC motor starting methods, making it a popular choice in various applications.

Smooth and Controlled Start-up:

- Gradually reduces initial high current , protecting the motor from damage and wear.

- Prevents sudden jerks and mechanical stress in connected equipment.

- Enhances comfort and safety in applications like elevators and cranes.

No-voltage coil (NVC): Automatically shuts down the motor in case of power loss, preventing accidents and damage.

Overload protection: Protects the motor from overheating caused by excessive current draw.

Simple and reliable design: Relatively easy to understand and maintain.

Limitations

- Not suitable for applications requiring precise and fully variable speed control.

- Energy Loss: Due to resistors are connected in series during starting huge power loss occurs

- Limited to DC Motors: 4 point starter is only campatible with DC shunt motor. can not be used with AC motors

Application of 4 Point Starter

4-point starter finds application in smoothly starting DC shunt motors.

Fans and Pumps: Ensuring gradual acceleration protects fan blades and pump impellers from excessive stress during startup.

Machine Tools: Maintaining controlled motor ramp-up prevents sudden jerks and improves machining accuracy.

Conveyor Belts: Smooth starting avoids product damage and potential spills on conveyor systems.

Elevators and Cranes: Controlled acceleration enhances passenger comfort and minimizes cargo sway in elevators and cranes.