3 Point Starter-Working Principle, Construction and Diagram,Disadvantage

3 point starter is used for shunt and compound DC motor. it is called a three-point starter because it has three terminals named L, F, and A.

The terminal named L must be connected to either side i.e the positive or negative side of the DC supply.

Terminal A must be connected to the one of motor armature terminals and F terminal to the shunt field terminal of the motor (any of two field terminals).

The final connection must then be made from second-line terminals on the main switch to a junction of the remaining two armature and field terminals of motors.

In this article, we are going to discuss, three-point starter working principle, Construction, the function of the No Volt release coil, and disadvantages.

Construction of 3-Point Starter

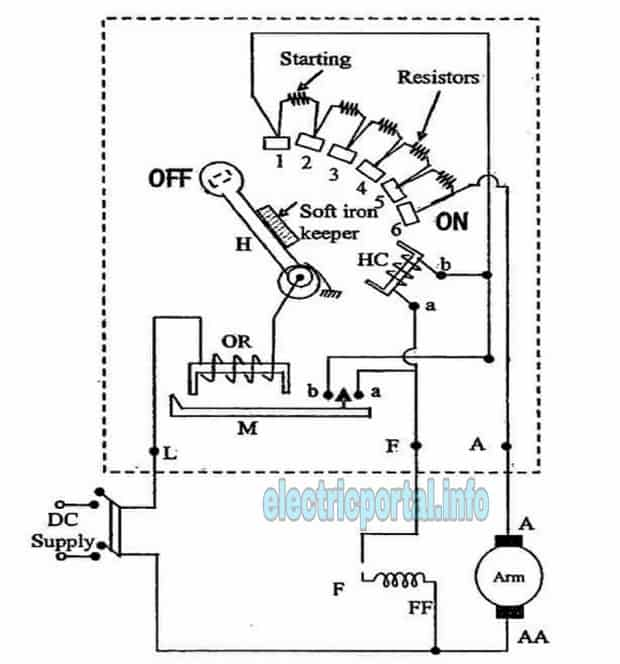

When the motor is at rest, a three-point starter handle “H” is placed at the “OFF” position by a strong spiral spring, the stud marked with OFF indicates the motor is disconnected from the main supply. and the starting resistance connected between studies 1, 2,3,4…6. the circuit diagram is shown in the above figure.

- “L” line terminal connected to the supply

- “A” Armature terminal connected to the armature winding

- “F” Field terminal connected to the field winding of dc motor

- “HC” Holding coil

- “OR” Overload Release

- “H” Handle

- “M” Movable Soft Iron

Working Of 3 point starter

For starting the motor handle “H” moved to the first stud indicated with 1. As soon as 3 point starter handle H touches stud 1. the shunt field and holding coil HC get connected in series across supply, On the other hand, the armature gets connected in series with the entire starting resistance.

Since the current start flowing through both field and armature winding.

The motor starts rotating. After attaining sufficient speed the handle H shifted to stud 2, Hence it cut down the resistance between stud 1 & stud 2.

The movement of three point starter handle continued till the soft iron keeper touches to the holding magnet. During the shifting of the handle from stud 1 to toward stud 6, the armature current decreases, and the speed of the dc motor rises exponentially.

In the final position, the electromagnetic pull exerted by holding coil will be greater than the force exerted by the spiral spring.

In this view, the handle “H” is held in ON position and the entire starting resistances are cut out. The holding coil HC is also called a NO-Volt release or low volt release.

Function of the No-Volt release Coil HC

- In the case of power failure, electromagnet HC gets demagnetized and the spiral spring brings back the handle (H) to the OFF position. In case of a power failure, the handle fails to return to the OFF position, The motor may get damaged if power is restored because there would be no starting resistance in the circuit.

- If the shunt field becomes open circuited accidentally HC gets demagnetized and handle H returns to the OFF position because of spring pull. In case the starter handle not released, speed starts increasing with the reduction in field flux. the small residual flux result in highly dangerous speed and the motor might get damaged.

Another protection device used in 3 point starter is the overload release which is connected in series with an armature circuit, Overload release “OR” is a small electromagnet, In case of armature current exceeds a present value due to overload “OR” become more strong and attract the movable soft iron “M” which is pivoted at one end.

Soft iron is attached to two terminals of HC coils a & b. Once OR attracted soft iron, terminals a & b of NO volt release coil get short-circuited.

In this manner HC coil gets demagnetized Three point starter handle is pulled back to the OFF position by a spiral spring and the motor gets disconnected from the supply.

The overcurrent on which overload release should operate can be adjusted by adjusting the distance between the electromagnet and movable soft iron M.

Disadvantages Of 3 point starter

- Three-point starters experience serious drawbacks for the application of motor with a large variation of speed by adjusting the field rheostat.

- If the speed above normal is to be required, the field current must be reduced. At a certain value of decreased field current, the electromagnetic pull of the holding coil (HC) becomes weaker than the spiral spring force, and the handle return to the OFF position, and the motor stop.

- So due to this application of 3 point starter are restricted and these problems are overcome in 4 point starter.