What is Soft Starter,Working Principle,diagram,advantages

What is Soft Starter?

Soft Starters are starting devices, used for the acceleration, deceleration, and protection of the three phase electrical induction motors through the controlling applied voltage to 3 phase motor.Induction motor is the most frequently used motor for industrial as well as domestic applications.

Most industrial motors are single phase or three-phase induction motors depending upon the supply fed to them. Ac motors have become most popular because of their simple and robust construction, low maintenance, and can be suitable for any working condition.

Due to its numerous applications, the induction motor needs some starting arrangements to start softly and safely. Various starting methods are used to start induction motors like star delta starter, DOL starter, auto transformer starter, and VFD. ( full form variable frequency drive).

In this article, we are going to discuss Soft starter for three phase induction motor, circuit, application, advantages, block and control diagram, working principle.

Soft Starter is another form of reduced voltage starter used for starting 3-phase induction motor. this Starter is also called a Solid-State controller.

Soft Starter does not change frequency as VFD. Instead it Ramp up voltage level applied to motor from initial value to full voltage.

This is the main difference between a Soft Starter and a VFD (variable frequency drive). Initially, the applied voltage is low which is only to overcome gear wheels or stretching driving belts etc. to avoid sudden jerks during the start. Gradually voltage increase, the torque also increases and the motor start to accelerate.

The advantage of this starting methods is the possibility to adjust torque as per exact need.

By the use of a soft starter starting current reduced, helps to protect the motor from taking a high starting current and also prevents a huge voltage drop in supply. This starter also provides a soft stop as a start. Hence it can be suitable where soft stopping is required like a conveyor belt or water pump.

The main benefits of using a soft starter are that the inrush current is reduced so that voltage drops on the network are avoided.

The torque is reduced which will decrease the mechanical stresses on the equipment and lead to a reduced need for service and maintenance and also to a longer life of the equipment.

Soft Starter Block diagram

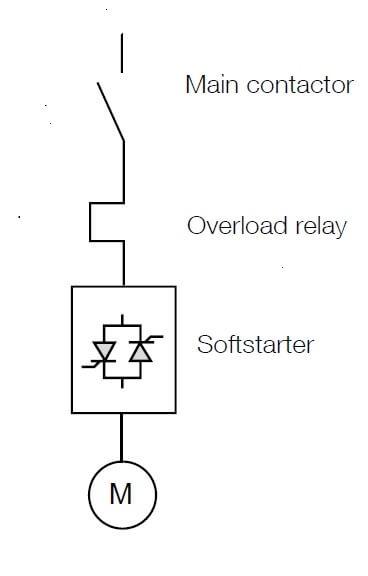

This starter contains only a few main components thyristor to regulate the voltage to the motor. In addition to this heat sinks and fans dissipate the heat to the environment.

Depending on the model of the starter, it can be equipped with a built-in electronic overload relay (EOL) eliminating the need for an external relay.

Soft Starter working principle

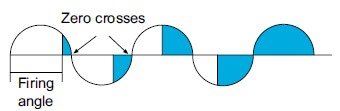

soft starter working principle is based on thyristor or SCR firing angle.

Where,

White portion= thyristor OFF

Blue portion= thyristor ON

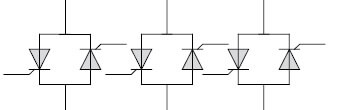

Soft Starter contains a number of anti-parallels connected thyristors. Each phase has a pair of thyristors.

A thyristor is a semiconductor device that is normally isolated but by applying a firing signal to the gate, it starts conducting and allowing current and voltage through it.

At the time of start to perform soft starting firing signal is sent to thyristors so that only the last part of each half period of sinusoidal voltage wave is passed through it.

After the start, the firing signal is sent earlier and earlier, to allow a bigger and bigger part of the voltage wave to pass through the thyristor.

Eventually firing signal is sent after every zero crossing to allow 100% voltage through the thyristor.

During stopping, the opposite action is done.

At first, the full voltage is allowed to pass through the thyristors and as the stop initiates, the firing signal is sent later and later allowing less and less of the voltage to pass through until the end voltage is reached. Then no more voltage is applied to the motor and the motor stops.

Start: The Thyristor allows part of the voltage through it initially and after increasing accordingly ramp-up time is set for starting.

Stop: The thyristor is in full conducting mode when soft stop begins, the voltage decreases as ramp time is set for the stop.

Voltage is reduced at starting hence current and torque also decrease.

if the voltage is decreased to 50% of the full voltage, the current will be decreased to about 50% of the maximum current at that speed and the torque will be decreased to about 25% of the maximum torque.

Ways of connecting the starter to the motor

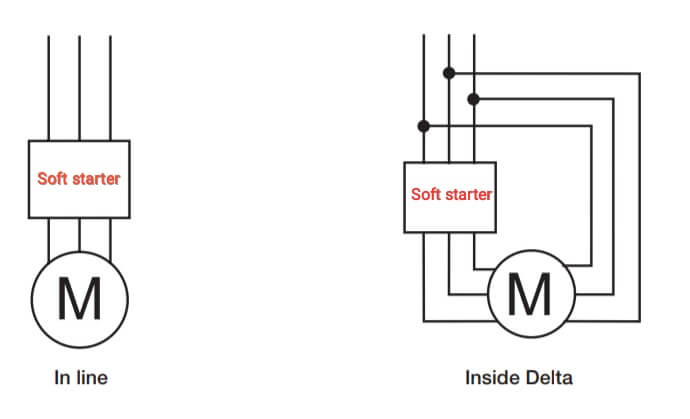

Inline connection

This way of connecting a starter is most common. All three phases are connected in series with the main contactor, overload relay, and soft starter following the motor.

In inline for 100A motor same rating(100A) starter required, overload relay, and main contactor required.

Inside Delta

The Inside Delta connection makes it possible to place the soft starter in the delta circuit and in that way, it can easily replace an existing star delta starter. order to achieve a more cost-effective.

When using Inside Delta, there are two options for the connecting main contactor; inside the delta circuit or outside the delta circuit. Both locations will stop the motor but in the inside delta circuit, the motor is still considered to be under tension.

In the outside delta circuit, the main contactor must be selected according to the rated current of the induction motor. In contrast, the contactor in the Inside delta circuit can be chosen according to 58% (1/√3) of the rated current.

Advantages

- Improved Efficiency: The efficiency of this starter using solid-state switches is more owing to the low on-state voltage.

- Controlled startup: The starting current can be controlled smoothly by easily altering the starting voltage and this ensures the smooth starting of the motor without any jerks this is the big advantage of the soft starter.

- Controlled acceleration: Motor acceleration is controlled smoothly.

- Low Cost and Size: This is ensured using solid-state switches.

- Enhanced Power Quality: limit the voltage drop and inrush current that can cause voltage sags and flickering lights. This helps maintain a stable power supply and prevents disruptions to other equipment connected to the same electrical system.

Disadvantages

- Higher Initial Cost: typically have a higher upfront cost compared to traditional motor starters. This can be a factor when considering the overall budget for a project or installation.

- Limited Voltage Control: Some soft starters may have limitations in controlling voltage across all speed ranges. This can impact the motor’s performance in applications that require precise control over the speed and torque.

Applications

find applications in various industries where controlled motor starting is essential. Some common applications include:

- Pump Systems: Soft starters are commonly used in water treatment plants, irrigation systems, and HVAC applications to control the starting and stopping of pumps. This ensures gentle acceleration and prevents hydraulic shocks.

- Conveyor systems: used in conveyor belts to provide controlled starting and stopping, reducing wear and tear on the belt and other mechanical components. This also improves the overall efficiency and reliability of the system.

- Industrial Fans and Compressors: Used in fan and compressor systems to achieve smooth acceleration and prevent overloads. This helps improve energy efficiency and reduces noise and vibration levels.

- Centrifuges and Mixer: employed in applications that involve centrifugal equipment or mixers to provide controlled acceleration and prevent material splashing or spillage.

I need the kind of soft starter.